YT24 air-leg rock drill is a high-efficiency rock drill machinery. It is widely applied to rock drivage and drilling of blast hole in various rock drill operations and is an important tool in such stonework as mine, railway, transportation and water conservancy construction.

This rock drill has a wide application range and is mostly applicable to drilling horizontal or inclined blast holes on medium-hard or hard (f=8-18) rocks, with the drilling depth of 5m. This rock drill can be used with FT140BD short-air-leg or FT140B long-air-leg rock drill according to the size of the tunnel section and can be installed on a drill carriage or drill mounting for work.

In order to protect good lubrication, the rock drill is provided with FY200B oil lubricator.

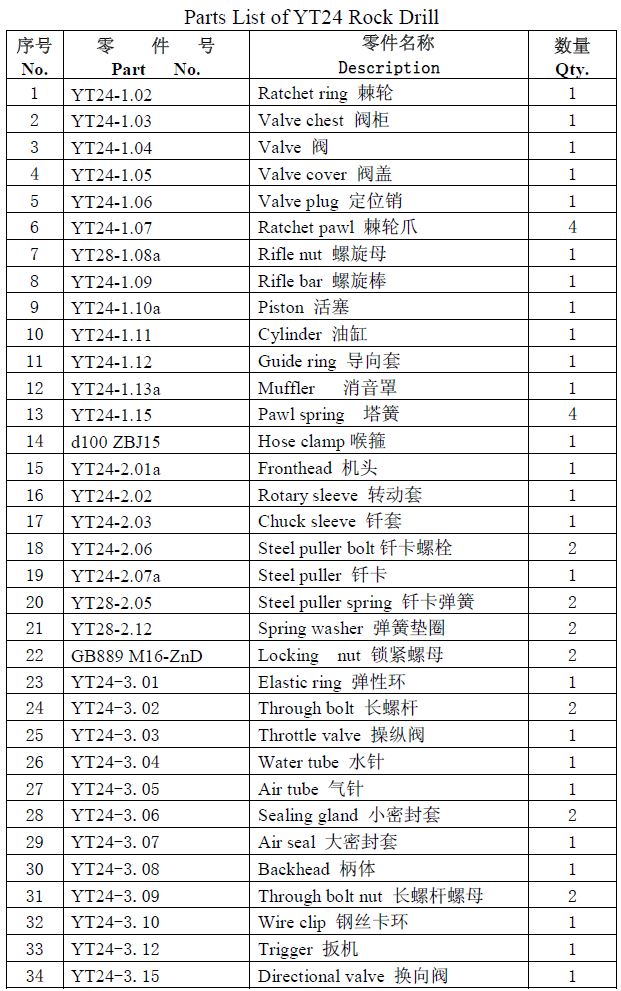

|

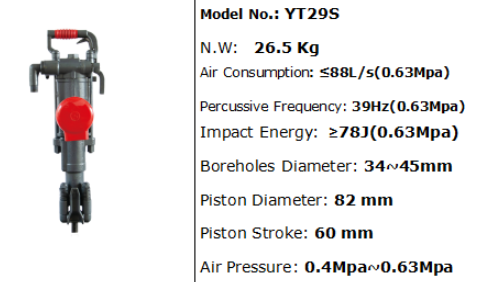

YT24 Rock Drill

|

|||

|

Weight

|

24kg

|

Length

|

678mm

|

|

Diameter of air cylinder

|

70mm

|

Piston stroke

|

70mm

|

|

Inner diameter of air pipe

|

19mm

|

Inner diameter of water pipe

|

13mm

|

|

Diameter of drill bit

|

34-42mm

|

||

|

Operating air pressure

|

0.4-0.63MPa (4-6.42kgf/cm2)

|

||

|

Frequency of impact *

|

≥31Hz (≥1,850 time/min)

|

||

|

Air consumption*

|

≤66.7L/s (≤4.0m3/min)

|

||

|

Specification of bit shank

|

22/108±1 (hexagonal diagonal/length)

|

||

|

|

* The performance parameters upon an air pressure of 0.63MPa

|

||

|

FT140B air-leg

|

|||

|

Length of air leg

|

1,687mm

|

Drilling length

|

1,250mm

|

|

Inner diameter of air cylinder

|

60mm

|

Weight

|

≈ 15.6kg

|

|

FT140BD air-leg

|

|||

|

Length of air leg

|

1,400mm

|

Drilling length

|

1,000mm

|

|

Inner diameter of air cylinder

|

60mm

|

Weight

|

≈ 13.9kg

|

|

FY200B Oil Lubricator

|

|||

|

Oil capacity

|

200ml

|

||

For more details please click PDF: YT24 ROCK DRILL

1. Before use, disassemble and clean new machine to remove anti-rust oil coated in the factory and then assemble it for use.

2. Before connecting the air pipe and the water pipe, blow off the filth in the pipes so as to prevent the filth from entering the machine to damage the mechanical parts.

3. Before use, check the flexibility and reliability of various operating gears and moving parts, fill the oil lubricator with lubricant and adjust the oil capacity well.

4. Before turning off the machine, cut off the water pipe firstly and let the machine run in light load for a while so as to remove the residual water in the machine, thereby preventing the inner parts from rusting.

5. Conduct regular maintenance and repair to machines frequently used and overhaul at least once one week to remove the filth in the machine and pay attention to replacing damaged parts or disabled parts.

6. Before storing the drill for a long time, disassemble, clean, oil and seal up it and store it in a dry place.

Contact: Lucy

Tel: +86 713 8906693

Whatsapp/Phone:+86 18186993613

E-mail: sales@superdrill.com.cn

|

|

|

|

|

|

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province