The elco hydraulic rock splitter is a kind of hand-hold splitting and demolition tool.It can controllably split rock or concrete.Especially suit for cabined area where large machine can not work.Such as hydraulic breaker and place where is strictly limited of noise,dust,flying debris,shake,exhaust gas,also widely use in the place where need non-explosive and blast forbidden.

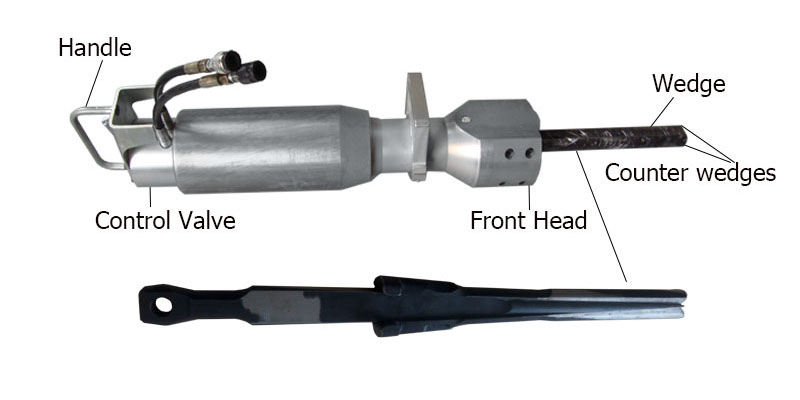

It is including Power Station and Cylinders.

<iframe width="560" height="315" src="https://www.youtube.com/embed/bOBBWuKTjvA" title="Hydraulic Rock Splitter Machine" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

Power Station:Diesel & Electric & Gasoline.

One Station can match 1-10 pieces cylinders.

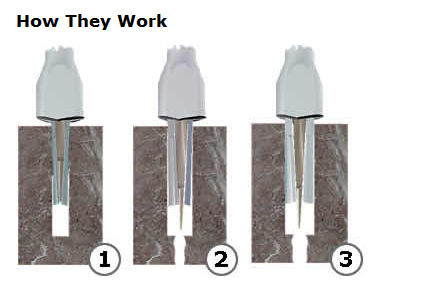

Principle and working method:

The hydraulic splitter uses the pressure provided by the hydraulic system to transmit the pressure to the splitting adze in the splitting machine, causing the adze blade of the splitting adze to expand and contract, thereby exerting a large splitting force to split rocks or other materials. open.

Phase 1, First, a hole of a precise diameter and depth is drilled into the material. The wedge set (one wedge and two counter wedges) is inserted into the drill-hole.

Phase 2, The wedge is driven forward under hydraulic pressure, forcing the counter wedges apart with a force of up to 450 tons. The material splits within seconds.

Phase 3, With enlarging counter wedges the split can be expanded to its maximum width. Reinforcing rods break or can be cut up with a suitable power tool.

hydraulic splitter---Hydraulic pump station

hydraulic splitter---Splitting gun and wedge

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province