<iframe width="560" height="315" src="https://www.youtube.com/embed/bOBBWuKTjvA" title="hydraulic rock splitter Machine" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share" referrerpolicy="strict-origin-when-cross-origin" allowfullscreen></iframe>

C12 Technical Data Sheet

| C12N | C12L | |

| Splitting force | 358t | 413t |

| Drill hole ∅ | 45-48 mm | 45-48 mm |

| Drill depth | 610 mm | 680 mm |

| Weight | 31 kg | 32 kg |

| Bar pressure | 500 bar | 500 bar |

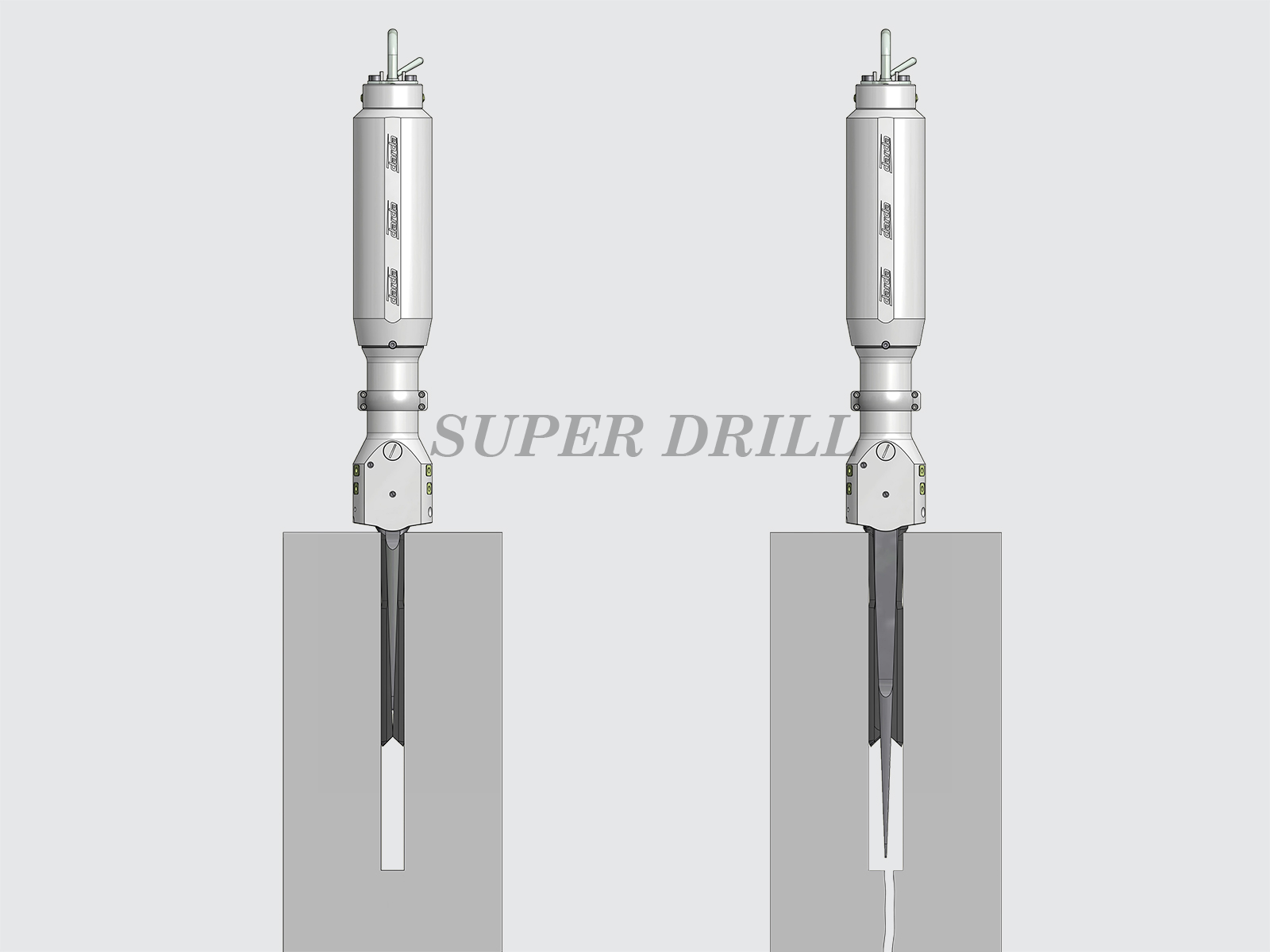

Taking advantage of the low tensile strength of rock and concrete, the hydraulic splitting cylinders allow controlled, quiet and cost-effective demolition from the inside!

Our largest hand-held cylinder model is the world’s most powerful splitter in relation to its size. The C12 splitting cylinder breaks reinforced, lightweight, as well as unreinforced concrete equally reliably and is particularly suitable for heading concrete piles, as well as wall and masonry demolition.

The C12 splitting cylinder is particularly suitable for rock demolition, as well as secondary splitting of boulders. Through several splits, the structure of a full rock surface or rock area can be weakened and the rock can be easily excavated afterwards. In the natural stone industry, it is used for block quarrying of hard rock, as well as in tunnel driving and extension work in underground mining.

The handy Rock and Concrete Splitter has an enormous power-to-weight ratio. One person can work in any position and even under water, while other work continues in parallel: Low noise, without vibrations and flying rocks.

Conventional mechanical methods destroy the structure of the material by applying external force. Rock and concrete, however, can withstand very large compressive forces from the outside. In comparison, the resistance to a force acting from the inside out is relatively low. The development of the Darda Rock and Concrete Splitter was based on this fact.

First, a hole of the appropriate depth and diameter is drilled, into which the splitting insert of the splitting cylinder is then inserted and aligned to determine the splitting direction. With hydraulic pressure, the wedge pushes itself between the two counter wedges and presses them apart. The effective splitting force of up to 413 tons or 4048 kN destroys the structure of concrete and rock from the inside. A split is created in a matter of seconds. Thinner reinforcing bars in reinforced concrete tear off.

Contact: sales@superdrill.com.cn

Phone: 86-18186993613

Tel: 86-18186993613

Company: Hubei Superdrill Equipment Co.,Ltd

Add: Building 3, Rainbow road,No.188 ; wuhan ;Hubei province